Article by Jimmy Arnold & Wade Hunter with photos by Fitz

(Lead photo of Bob Sweeney and supporting photos of the fellow “Dawn Brewers” on the 24th of July at O’Connor brewery)

Located just a few trendy blocks from the center of Ghent is a modern beer drinkers’ oasis. O’Connor Brewery is so much more than a just that; it’s our local hall and hangout. As a work of art in itself, their stage is evidence of that, hosting all sorts of events that highlight the surrounding community and its entertainment offerings such as the very successful O’Connoroo festival. When sampling beers fresh from the source at the taproom, one may find many events accompanied by some of the most inventive food trucks and pop-up restaurants’ offerings, making it a complete gastro-experience no matter what may have brought you there. All of that said, brewing beer might be popular among backyard hobbyists, but this is not your brother-in-law’s’ home brew. A tour of O’Connor made apparent the complexity of the process on a scale that would turn your aforementioned inlaw gray overnight―where 465,000 gallons of hoppy goodness passes through the process annually. Production manager Bob Sweeney and his team led the charge of showing Southern Grit every meticulous step of the process of making their beer… have a look…

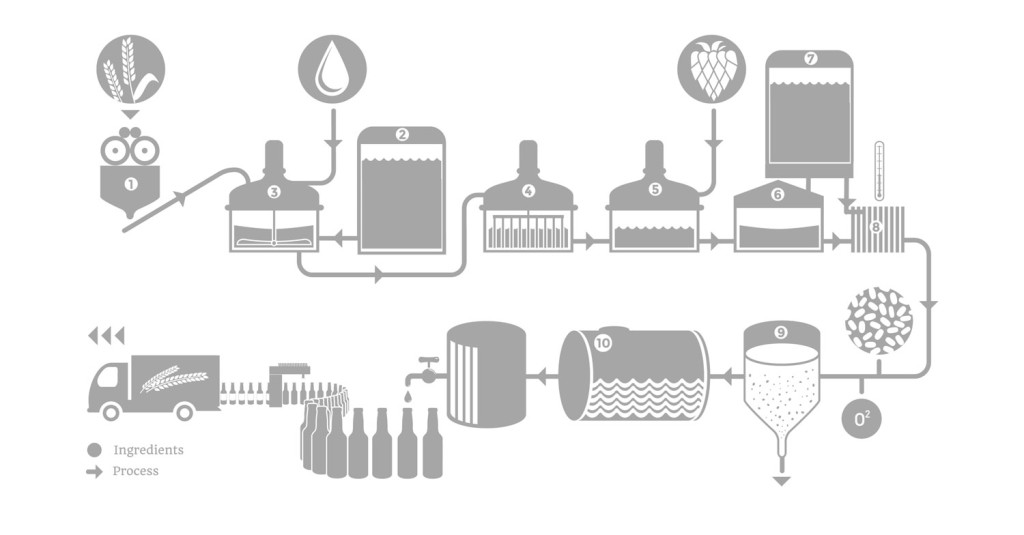

From 1300 to 2200 lbs. of grain are ground for each brewed batch by the (1) Mill and then transferred with husk as grist. Hot liquor (i.e., water), at a temperature of 149-153℉ from the (2) Hot Liquor Tank, is added to the grain and mixed in the (3) Mash Tun to aid starches into sugar conversion. After a period, the liquid mix is then moved to the (4) Lauter Tun, where it is separated into wort (a solution of water and sugars) and the mash (the leftover grain) through a process called lautering. The now wort is removed by aid of grates on the floor of the container, whereas the spent grain is utilized as cattle feed. After advancing the wort to the (5) Wort Kettle, the coagulant Irish Moss (a type of seaweed extract) and fresh hops (if used, for bitterness) are added to the batch and it is brought to a boil. After boiling, hops may be again added, this time for flavor. Once inside of the (6) Whirlpool Tank, a jet of hot liquor is implemented to vortex the mash, permitting the solidification of a column of hot trub (the particulate constituents of the prior processes) at the center of the container. Once purified, the wort is cooled by passage through a (8) Heat Exchanger, which in turn warms liquor from the (7) Cold Liquor Tank for topping off the Hot Liquor Tank in an effort to save energy. Afterward, yeast is pitched into the wort and oxygen is infused to create the ferment while within the (9) Fermentation Tank. After 10 to 14 days, the ferment has reached peak fomentation and the brew is siphoned off of the dead yeast and hops for transferral to the (10) Bright Tank, at which point it is rested and preparation for kegging or bottling occurs.

(Skylar Sickles taking a gravity reading using a refractometer)

(Joe Simons dropping yeast out of the fermentation tank)

Visit O’Connor online at www.oconnorbrewing.com

Visit O’Connor facebook at www.facebook.com/OConnorBrewing

No Comments